They don’t go in the same level of detail. This is useful when sharing it with teammates or clients. By nudging causes closer to one another, an Ishikawa diagram makes it easier to see the entire problem in a compact way. Here’s another point that might sound trivial but can matter: issue trees tend to be extremely space hungry: ten pages is pretty common to capture an entire tree. Not a big deal but in Western countries we’re used to flowing when moving from right to left, so you might feel more comfortable with the layout of an issue tree. Ishikawa diagrams go to the original question as you read them from left to right. Ishikawa diagrams and issue trees are different in three ways: Ishikawa diagrams and issue trees are different You can either develop the set specifically for that problem or use one of the standard frameworks. So, if you decide to use an Ishikawa diagram, don’t blindly follow the 4 Ms + E approach instead ensure that you build your diagram on an appropriate set of dimensions, as set that’s both MECE and insightful. It’s applying third and the fourth that has all the fun.

#Online ishikawa diagram free#

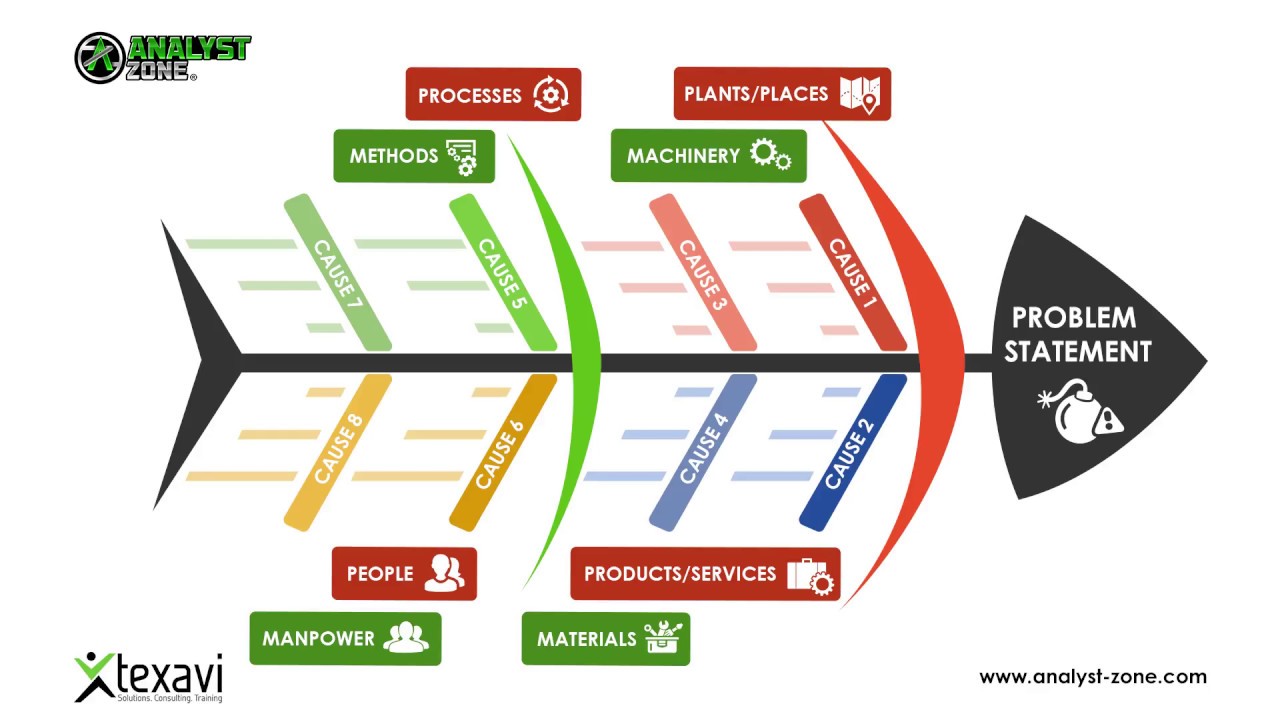

Kaoru Ishikawa developed fishbone diagrams as one of the seven “tools of quality”: -1- the histogram, -2- the scatter diagram, -3- the Pareto chart, -4- the Ishikawa diagram, -5- the statistical process chart, -6- the flowchart, and -7- the checksheet ( source (for a book) another source for a free online resource). Each type branches out into smaller types, thereby somewhat mimicking the bone structure of a fish. Having the problem at the right of the diagram-on the fish head-they spell out all the possible causes on the left, sorting them out by types. Ishikawa diagrams have many names: they are also called cause-and-effect diagrams, fishbone diagrams, or even Fishikawa diagrams. Ishikawa diagrams and issue trees are alike So let’s look how it differs from our de-facto diagnosis tool: the why issue tree / issue map.

We hope these charts will facilitate brainstorming by foundry teams as they explore the reasons for a specific defect, by process of examination and careful elimination of non-applicable variables.Say “root cause analysis” in any cocktail party and you’ll hear back “Ishikawa diagram.” Ok, that might work only with cocktail parties that cater to engineers, but an Ishikawa diagram is the de-facto tool of many to diagnose a problem. These ‘cause-and-effect’ analysis charts, limited to 6 major casting issues, account for almost 90% of casting problems related to green sand moulding. In pursuit of MPM’s spirit of sharing our decades of know-how in green sand management and control, our team of experts have created readymade FISHBONE Diagrams for problem solving and quality control in foundries. It's a way of life for foundrymen in QC and rejection meetings! What do foundrymen have to do with fishbone diagrams? Plenty! By continuous use of this method, process variables are updated and the accuracy and speed of achieving focused outcomes is vastly improved. Ishikawa diagrams were popularized in the 1960s by Kaoru Ishikawa, who pioneered quality management processes in Japan which then spread throughout quality circles globally.įishbone Diagrams are very useful when all variables are known.

0 kommentar(er)

0 kommentar(er)